Applications

Textile

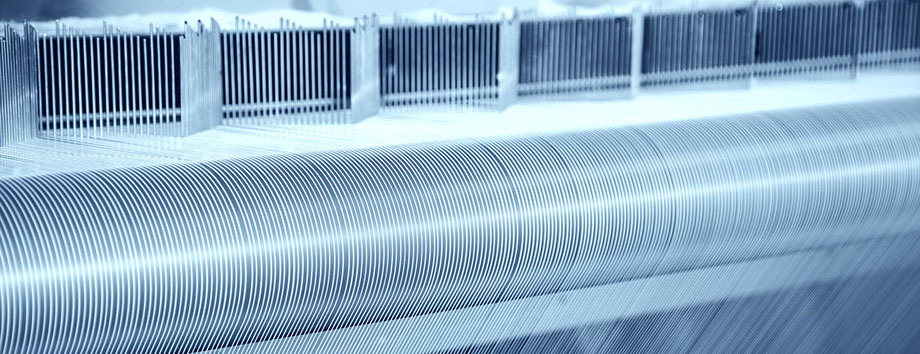

Cambridge Nanolitic provides coating on critical components of textile and packaging industries for leading European Manufacturers. Textile parts benefit from yarn friendly nanoceramic surface which does not cause snowing effect and significantly prolongs their operational life.

Packaging industry components

They are protected from wear caused by abrasive packaging materials. Use of Aluminium with nanoceramic surface enables to efficiently remove heat from friction areas.

Automotive

Low friction, wear resistant nanoceramic surface enables to use light weight Aluminium with ceramic surface instead of steel for a variety of applications. Al is about three times lighter than Steel. Combination of light weight and low friction coefficient is beneficial for fast moving parts and/or those that suffer from erosion and wear.

Biocompatible coating for metal implants

Nanolitic Technology enables building nanostructured ceramic layers on Titanium, Zirconium, Niobium and Magnesium alloys with desired functionality including chemical and phase composition, density, roughness and thickness. Coating has highly developed surface with submicron pore size and controllable topography. Surface is characterised by exceptional wettability and capability of carrying medication or HA. Ceramic layer creates a barrier between metal and tissue and prevents metal penetration. Coated surface has natural white colour on all Ti alloys, including Grade 5 Ti-6Al-4V.

Corrosion Protection

Atmospheric and chemical corrosion protection for Mg and Al materials for structural components (transport vehicles), phones and other mobile devices.

Plasma erosion protection

Electrodes and elements for plasma reactors.

Electronic applications

Dielectric layers for various applications.